Noam Naveh

CEO @Stylib

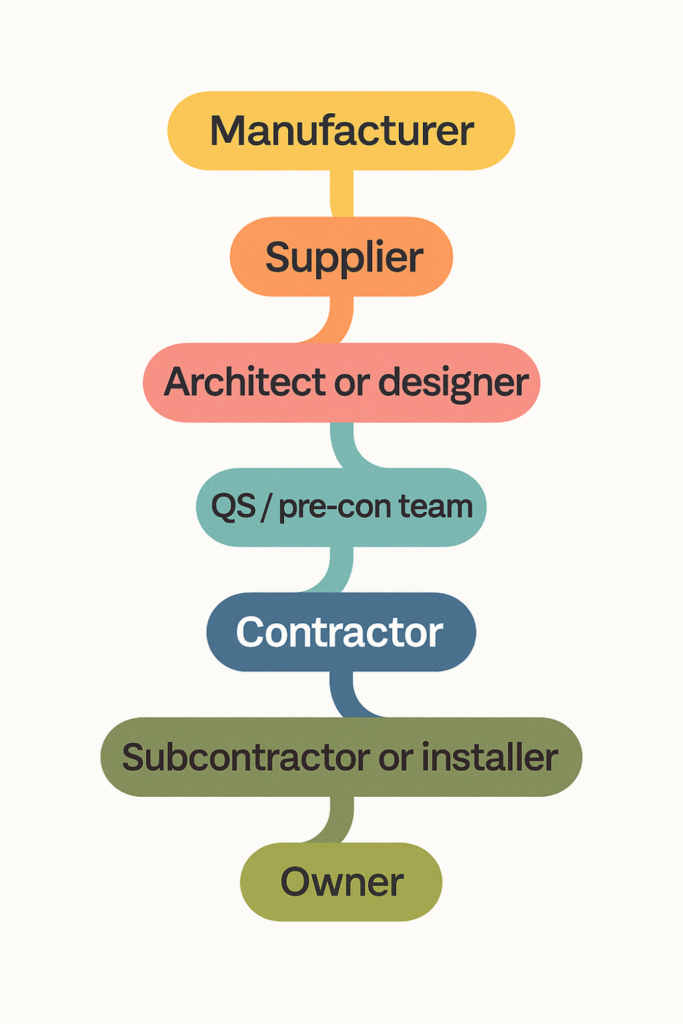

Data structured at source would often not reach the end of the supply chain. Image source: StylibData structured at source would often not reach the end of the supply chain. Image source: StylibThe AEC industry tends to think of supply chains in terms of materials. Products are made, shipped, and installed. But in the world of architectural products, the supply chain starts much earlier – and it starts with data.

Before a tile is cut or a light fitting is ordered, the data describing that product has already travelled through five or six hands. And if that data is incomplete or degraded, the product might never make it to site at all.

Construction supply chains are unique

In most industries, the distance between product selection and installation / use is relatively short. Think about nearly any e-commerce category like clothes or homeware. Products are often selected, paid for, and delivered within days – sometimes even hours.

But in construction, that timeline usually stretches across months or even years. Products might be selected at concept stage, but don’t get procured until the building is nearing completion.

But that’s only one part of the story. What matters even more is the number of different stakeholders who interact with the data along the way. Consider this typical example where the supply chain is easy made of 7 different organisations, from the manufacturer to the supplier to the architect, QS, contractor, installer and owner.

Each entity needs different aspects of the product data, and reprocesses the information in line with the documentation it produces – from marketing materials to tender documents. And like in the Chinese secret game, almost each time the data moves hands, something is lost.

What gets lost along the way?

An architect reaches out to a supplier with a product related question. They hear back something like ‘Oh I’m not sure, I’ll have to check with the factory’. Next time you hear from them is a week later.

If you’re an architect, this is probably all too familiar.

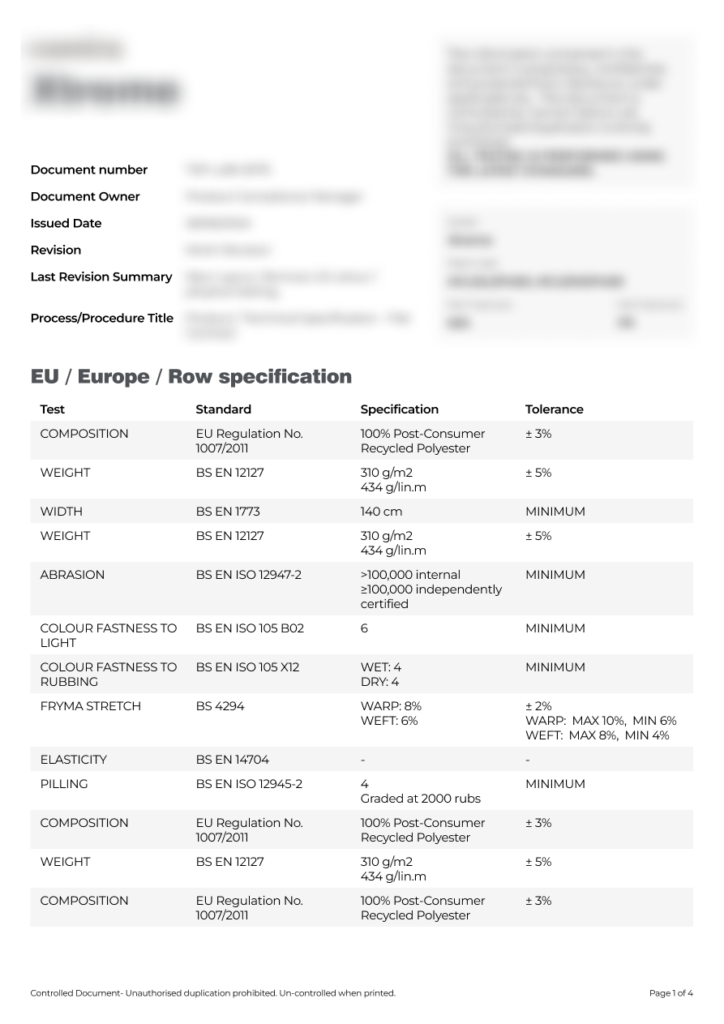

Structured, accurate product data often starts its life in a manufacturer ERP or PIM system. But as it moves downstream, it gets repackaged into PDFs, brochures, websites, spec schedules, word docs, excel sheets and more.

But when transitioning from one format to another – even between departments of the same company – critical product data often gets lost in transition.

Here’s some common phenomenon:

- Product information gets removed due to layout restrictions

- Structured specs become unsearchable as they move from tabular to images and pdfs

- Data like sizes lose units or formatting

- Certifications go missing

The result is degraded data. And degraded data leads to compromised decision making as we’ll see next.

So what?

At this point you might say, ‘Well ok, but everything works right? manufacturers sell, designers specify and contractors build’. True. But consider these example side affects of these data hick-ups:

- A designer visits a supplier’s website. They re looking for sustainability credentials of a product they’re reviewing. But… they can’t find them. The data exists at the manufacturer level – but the supplier didn’t include it on their site. The designer moves on. Lost business.

- A client is trying to identify a cost-effective alternative during a value engineering process. All they have is the finishes schedule, with generalist product detail. Matching performance properly would take too long, so they base their VE brief on what’s available: name, size, maybe colour. The result is a poorer product going into the next spec.

In both example the data did exist somewhere.

It simply ‘got lost’ when travelling down the supply chain.

What good looks like

So what does a strong data chain actually look like in practice? Here’s what we’ve seen work:

- For manufacturers: Data is structured from the start. Specs, certifications, formats and performance claims are clearly defined and stored in a usable format. All of this information is made easily and openly available online so anyone in the chain can access it.

- For suppliers: That data is preserved and repackaged without losing fidelity. The story might change, but the facts stay intact. If rebranding, all original manufacturer data should still be present and clearly referenced. Product pages should hold the complete set of technical details so nothing is lost when moving from manufacturer to supplier.

- For designers: Products are described in full in all relevant design packages, with attributes like fire rating, acoustic class, or certifications included. Critical specification details are embedded directly into schedules so downstream stakeholders understand not just what was selected, but why.

So in short: Structured at source, preserved through every handoff and alway trackable.

How Stylib helps

For manufacturers, we structure information, make it easily exportable in its entirety, and ensure assets are always accessible through our integrated CDN. We offer this as a supported service using our Hub software – the only native architectural products catalogue management solution in the market.

For suppliers, we help ingest manufacturer data and export it in full so nothing is lost in transition. This means suppliers can maintain the completeness and accuracy of the original data while presenting it in a marketable way. This is also delivered through our supported Hub service, ensuring a consistent, central source of truth for product information.